Principle and Working:

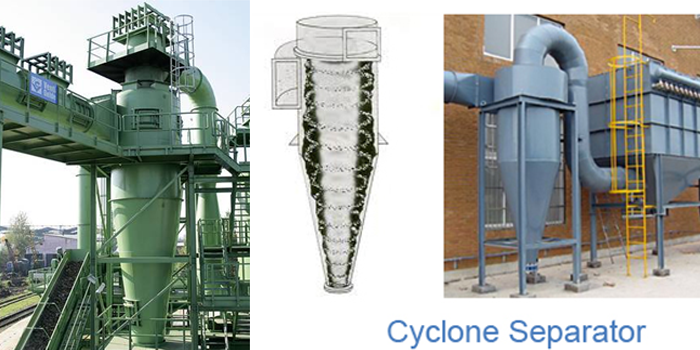

A high speed rotating (air)flow is established within a cylindrical or conical container called a cyclone. Air flows in a spiral

pattern, beginning at the top (wide end) of the cyclone and ending at the bottom (narrow) end before exiting the cyclone

in a straight stream through the center of the cyclone and out the top.

Larger (denser) particles in the rotating stream have too much inertia to follow the tight curve of the stream and strike

the outside wall, falling then to the bottom of the cyclone where they can be removed. In a conical system, as the rotating flow

moves towards the narrow end of the cyclone the rotational radius of the stream is reduced, separating smaller and smaller particles.

Applications:

General applications include: